2019-2020 Catalog [ARCHIVED CATALOG]

Machining Technology Program

|

|

Men and women working as machinists, create precise mechanical parts and tools for engines and other automated products using power-operated machines. In addition to operating technical machinery, machinists are also responsible for reviewing product blueprints and specifications, planning and troubleshooting the production process, and ensuring the accuracy of the finished product they create.

The Machine Technology operator/programmer certificate and degree programs are designed to prepare graduates for careers in the manufacturing industries. Topics within the programs include blueprint reading, computer-aided manufacturing (CAD CAM), machine shop math, extensive hands-on set up, and operating manual lathes and mills, as well as operating, and programming CNC machine tools.

Machine Tool Technology is classified as an evolving occupation and the demand in careers for machinists is projected to remain steady and provide future employment growth and economic competitiveness within Texas.

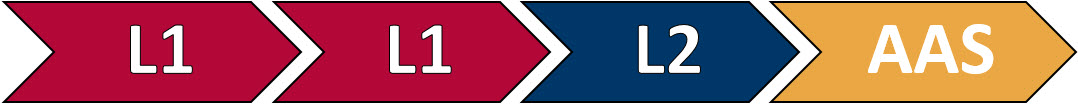

The program contains a progressive sequence of curriculum, with awards earned at milestone intervals.

By completing the entire program, students will earn four awards:

- Machinist I, Level 1 Certificate

- Computer Numeric Control Operator/Programmer I, Level 1 Certificate

- Computer Numeric Control Operator/Programmer II, Level 2 Certificate

- Machining Technology, AAS

Machinist I, Level 1 Certificate

[C1_MAC1 certificate offered at LSC-CyFair, LSC-Montgomery, LSC-North Harris and LSC-University Park] Total Credit Hours Required for Certificate: 21 The Machinist I Certificate Level I is often referred to as “manual machining”, as in the operator manually controls the machine as opposed to a computer. The manual Machinist student will be taught material properties, blueprint reading, and precision measuring tool use, precision layout and set up, machine shop mathematics, the safe operation of manual lathes, mills and drills to manufacture precision parts. Manual machinists are skilled, dexterous individuals who drill, cut and shape items with precision machine tools. Working in industrial shops or plants with blueprints and specifications, machinists produce anything from springs to aerospace parts. This is the required foundational set of skills to move into the Machine tool technology career and it stacks (builds) onto the other machining certificates to eventually yield the student if desired the AAS degree in Machining Technology.

| Level 1 Certificate Awarded |

Computer Numeric Control Operator/Programmer I, Level 1 Certificate

[C1_CNA1 certificate offered at LSC-CyFair, LSC-Montgomery, LSC-North Harris, and LSC-University Park] Prerequisite: Completion of courses shared with the Machinist, Level 1 Certificate: - MCHN 1302 - Print Reading for Machine Trades,

- MCHN 1338 - Basic Machine Shop I,

- MCHN 1343 - Machine Shop Mathematics, and

- EDUC 1300 - Learning Framework: 1st Year Experience

Total Credit Hours Required for Certificate: 22 Computer Numeric Control Operator/Programmer I Certificate also referred to as CNC 1 is a continuation of the skills learned in the Machinist I Certificate. In this certificate the machinist student is taught computer numeric control (CNC) programming and operational skills to successfully operate/program 3 axis machining and 2 axis turning centers. These are the same basic type of machines (lathe, mill and drill) as in the manual program except they are more precise, faster, student programed, and computer controlled. The student in this certificate is taught the industry standard in design and programming through CAD/CAM (computer aided design / computer aided manufacturing) software.This is the next step, the next set of skills to move into the machine tool technology and manufacturing career and it stacks (builds) onto the next machining certificate to eventually yield the student if desired the AAS degree in Machining Technology.

| Level 1 Certificate Awarded |

Computer Numeric Control Operator/Programmer II, Level 2 Certificate

[C2_CNC2 certificate offered at LSC-CyFair, LSC-Montgomery, LSC-North Harris, and LSC-University Park] Prerequisite: Completion of Machinist, Level 1 Certificate AND Computer Numeric Control Operator/Programmer I, Level 1 Certificate Total Credit Hours Required for Certificate: 45 Computer Numeric Control Operator/Programmer II Certificate also referred to as CNC 2 is the final machining technology certificate and is an advanced continuation of the skills learned in the Computer Numeric Control Operator/Programmer I Certificate (CNC). In this certificate the student machinist is taught advanced computer numeric control (CNC) programming and operational skills adding 2 more axes of rotation therefore the student learns to successfully program/operate 5 axis machining and multi axis turning centers. The student in this certificate is taught advanced levels of design and programming through industry standard CAD/CAM (computer aided design / computer aided manufacturing) software. This is the final set of machining skills which has built upon the previous two certificates (Manual and CNC 1) to prepare the student to enter a machine tool technology and manufacturing career. After this certificate the student can obtain the AAS if desired by taking 9 credit hours of academic courses and an additional 3 credit hour machining course.

| Level 2 Certificate Awarded |

Machining Technology, AAS

[AAS_MCHN offered at LSC-CyFair, LSC-Montgomery, LSC-North Harris, and LSC-University Park] Prerequisite: Completion of Computer Numeric Control Operator/Programmer II, Level 2 Certificate Total Credit Hours Required for Certificate: 60 The Machining Technology, AAS degree is the final set of instruction in the machining technology program. The Machining Technology, AAS degree contains all the skills, training and knowledge gained in the stackable machining certificates (Manual, CNC 1 and CNC 2) which includes material properties, blueprint reading, precision measuring tool use, precision layout and set up, machine shop mathematics, the safe operation of manual and CNC lathes, mills and drills, (CNC) programming and operational skills to successfully program operate and manufacture multi axis parts. The remaining course work required for the AAS after earning the previous machining certificates is 4 courses (3 academic and 1 machining). Although the Machining Technology, AAS is the final, terminal machining degree offered it is not a terminal degree for the student. The AAS can be applied towards a 4-year BAAS (Bachelor of Applied Science) at several Texas State Universities.

|

|

|

|

|

|